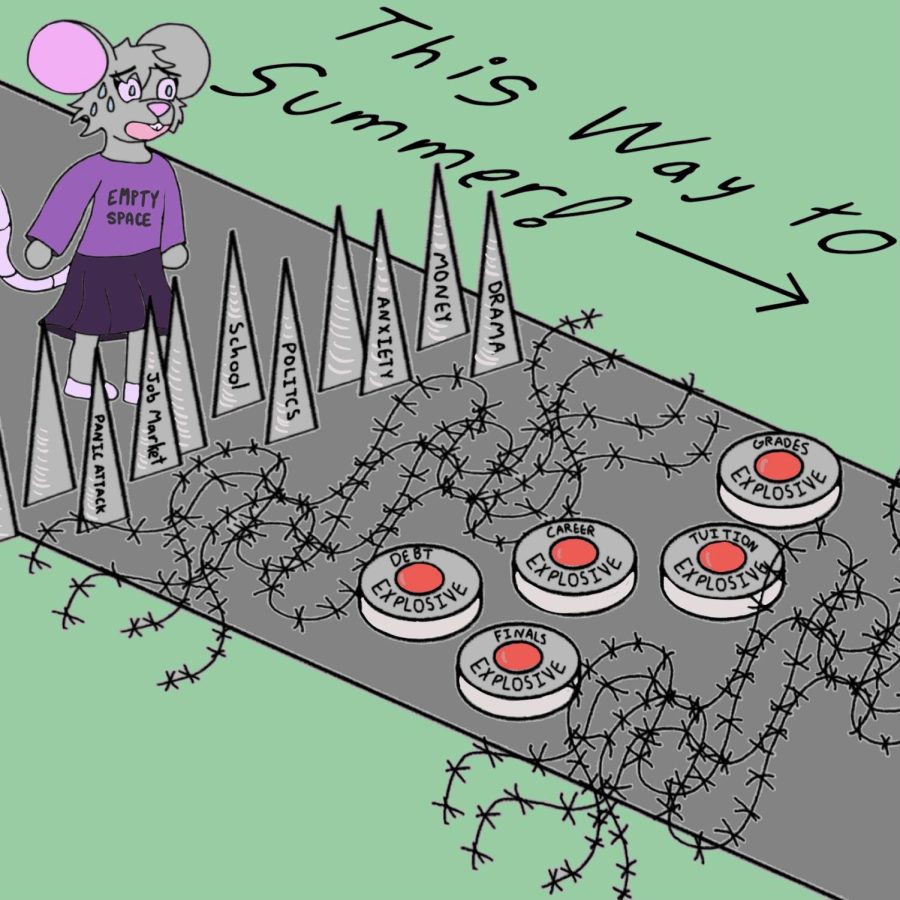

Class is starting in a few minutes and you are pressed for breakfast.

Luckily, a basket of muffins sits out on your table. You grab one and as you rush out the door, take a big bite, wrapper and all.

The moist, sweet blueberry batter melts in your mouth – along with the wrapper. In fact, you hardly noticed the wrapper as you made your way to class and wiped the last bits of crumb off your cheek. No waste, just a full belly.

It sounds like science fiction, but Yanyun Zhao, a distinguished professor in Oregon State University’s Department of Food Science and Technology has been developing sustainable packaging for over 20 years.

She started her work in animal product packaging, but has extended it to include edible packaging, edible coatings and converting biological waste into compostable packaging.

“Dr. Zhao’s lab has opened my eyes to countless untapped opportunities in the sustainable food processing and packaging space and to the many challenges that come along with developing sustainable solutions in the food system,” said Emma Gordy, a graduate research assistant in Zhao’s lab.

Much of Zhao’s recent work has been tackling the reduction of single-use plastics.

At an Agricultural Summit event during the summer, she put some of her research on display. Unrolling a fruit-leather snack from its plastic-looking sheen, she explained how her lab was able to make the edible coating out of cranberry fruit pumice – to compliment the flavor of the fruit leather.

“I don’t think edible packaging replaces everything. That’s impossible. Plastics … there’s a reason why they’re there. They have some unique functionalities and they’re cheap, right? But edible packaging can solve part of the problem, especially single use plastics,” Zhao said.

The edible packaging has also extended to muffin-liners made of starch, which, according to a recent paper, taste just as good as the muffins themselves.

“We love seeing the comments that we received (on the paper). Each is so promising,” Zhao said.

Zhao also held up a serving of instant coffee, packaged in plastic (or what looked to be). When submerged in the water, the packaging diffuses and leaves a completely drinkable cup of coffee behind.

But edible packaging isn’t the only way Zhao’s work is reducing waste. When people make wine or apple juice, the leftover skin and fiber found in the machinery is called pumice.

“That’s a huge waste and you cannot dump it in the field. You have to compost it. It’s very expensive.” Zhao said.

The research team has been able to find a new use for the pumice waste: upcycling this waste into an alternative fiber to make multi-paper packaging.

By suspending the pulp in water and vacuum-pressuring the solution into specific molds, Zhao and her team have been able to mold this pumice into egg cartons, package cushioning, takeout containers, berry/fruit baskets and more.

According to Gordy and Zhao, many of these items have been previously made of recycled newspapers and magazines. But the reduction in print media has reduced those resources. Fruit pumice is a compostable alternative.

But Zhao and her team are also working on another solution to biological waste.

In the last few years, smoke from wildfires in Oregon and Northern California have decimated wine production. That smoky taste and smell that can elevate some flavors, often reduces a wine to tasting like an ashtray.

Many grapes must be thrown out as a result.

The biological molecules primarily at fault are called phenols, and are readily absorbed by grape skins. Zhao, in conjunction with a number of other research teams, has created a coating that can be sprayed on grapes and absorb the phenols instead.

This is building off Zhao’s previous work in creating edible coatings.

“The edible coating can extend the shelf life of bananas and apples – anything!” Zhao said.

With so many positive results and applications, it’s easy to wonder why you can’t go into the grocery store and grab a fruit-pumice carton of eggs.

There is an abundance of technology and knowledge in this area of sustainability and food research, but the patent, licensing and manufacturing process are full of as many obstacles as the research. Much of the research is still ongoing as well.

“Science is a messy process,” Gordy said. “Literally and figuratively when working with bio-waste materials.”

While private companies have licensed some of the research, it will likely not be commercially available for a while.

“The implementation process inevitably comes with many setbacks before the desired outcome is achieved,” Gordy said.

Until Zhao’s research hits the market, the rest of us will have to watch out for those muffin wrappers.