Carbonated Cement

May 16, 2016

OSU researchers design more sustainable cement

OSU researchers recently discovered a new approach to producing cement which, if widely implemented, could offer environmental benefits, such as reducing greenhouse gas emissions and water consumption, as well producing a more durable concrete.

A recent study published in “Construction and Building Materials”, written by engineers from Oregon State University, Purdue University and Solidia Technologies, outlined the new form of producing cement, called carbonation.

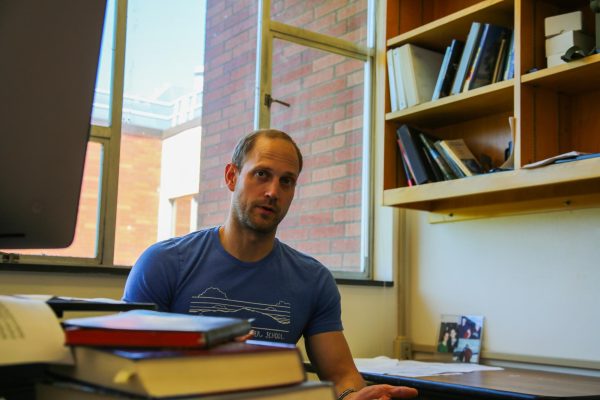

“With conventional concrete, water comes together with cement to form a glue, called hydration,” said Jason Weiss, the Miles Lowell and Margaret Watt Edwards Distinguished Chair in the OSU college of engineering. “In this newer type of concrete, instead of water reacting with cement, it’s carbon dioxide, water and cement reacting.”

This new process, called carbonation, would reduce carbon dioxide emissions during production and would be environmentally sustainable, according to Weiss.

“When cement is manufactured, carbon dioxide is produced, and we use so much concrete around the world that there tends to be a lot of carbon dioxide released into the atmosphere,” Weiss said. “The process of manufacturing this new cement would result in less carbon dioxide because the reaction consumes, instead of produces, carbon dioxide.”

Not only would this carbonated cement reduce greenhouse gas emissions, it would prove to be more durable due to its ability to be resistant to deicing salts, Weiss said.

“Conventional concretes have something called calcium hydroxide that’s part of the glue that forms, and deicing salts react with it to damage the concrete,” Weiss said. “This new concrete doesn’t have calcium hydroxide, making it less likely to be damaged.”

The production of carbonated cement would be similar in cost to conventional cement. Because two to four tons of cement are produced each year, the current manufacturing system is not very open to change, which would be the largest obstacle the production of carbonated cement would face, according to Weiss.

“The biggest challenge is we have been producing conventional concrete for a long time,” Weiss said. “The industry is setup to produce conventional concrete, not carbonated concrete, which may take time to reverse.”

Solidia Technologies is currently working on producing the materials necessary to manufacture carbonated concrete. In order to integrate this new cement, OSU engineers are working towards public awareness, according to Weiss.

“Right now people need to understand what this concrete is, its background, how it fits into building codes and what its benefits are,” Weiss said. “Right now we are working with Solidia Technologies to do this.”