Oregon State University receives $810,000 grant from Walmart to research environmentally friendly dye

February 9, 2016

The Walmart Foundation, the world’s largest retailer, gave Oregon State University an $810,000 grant to research sustainable and environmentally-friendly ways to dye fabric. The plan is to use continuous digital printing and the drying of biopigment inks. Pigmented ink is made of fine powder suspended in a liquid carrier.

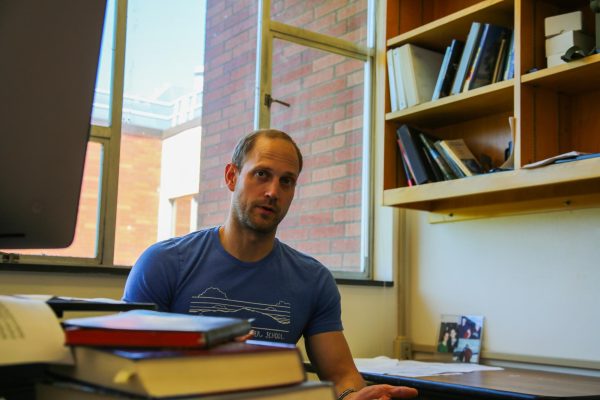

Four OSU professors from different departments have been chosen to collaborate on the textile research project – Alex Chang from the College of Chemical Engineering, Hsiou-Lien Chen from the College of Business, Sara Robinson from the College of Forestry and Wildlife and Rajiv Malhotra from the College of Manufacturing Engineering.

“I really look forward to working with the three other professors, I like the collaboration because we can each bring different ideas,” Chang said.

The four professors plan to start fully working on the research project in the beginning of March 2016 and hope to have significant results within the next three years.

“How this idea started was that Professor Robinson found a special fungi that can produce different biopigment,” Chang said. “Now, our job is to turn that biopigment into ink. We are also working Xerox’s printing technology in Wilsonville.”

“Together we hope to create a new drying technique using light photon energy to dry the ink faster and more efficiently,” Chang said.

Walmart is searching for more inventive ways to create and fabricate their products. According to a press release, the company views “higher education as the key to innovation,” and the U.S. Conference of Mayors partnered with Walmart on the program to help increase production jobs.

In Jan. 2013, Walmart announced their plan to help revive U.S. manufacturing by buying an additional $250 billion in products that support U.S. jobs by 2023. However, in Jan. 2016 Walmart recently announced 154 U.S. stores are closing, including two in Oregon.

Ronald Becker is the manager of the Model Shop Sample Room at Adidas in Portland. Adidas is also using alternative ways for drying and manufacturing products.

“Our 3D printing is incredible because you can just print what you want to use and not worry about dying,” Becker said. “I think a huge retail store like Walmart would turn to 3D printing.”

“We also currently use a process called sublimation printing which is printing ink on transfer paper followed by direct heat and pressure which transfers it to a gas and onto the fabric,” Becker said. “Sublimation process is a water based ink and we use heat or UV curing for the drying.”

Kathleen McLaughlin is the president of the Walmart Foundation and chief sustainability officer for Walmart.

“The U.S. Manufacturing Innovation Fund is part of Walmart and the Walmart Foundation’s broader commitment to foster new economic growth and opportunity and create stronger communities,” said McLaughlin in an article published by Walmart News.

Over the course of the next five years, each year the Walmart Foundation will grant the five leading research and academic schools in the country a total of $2.84 million in donations for their research focused on textile production innovations.

In addition to OSU, the other four schools to win the 2016 Walmart grant were Clemson University, University of Texas at Austin, North Carolina State University, and Cornell University.