OSU Cheese continues to grow after its reopening in 2010

January 6, 2020

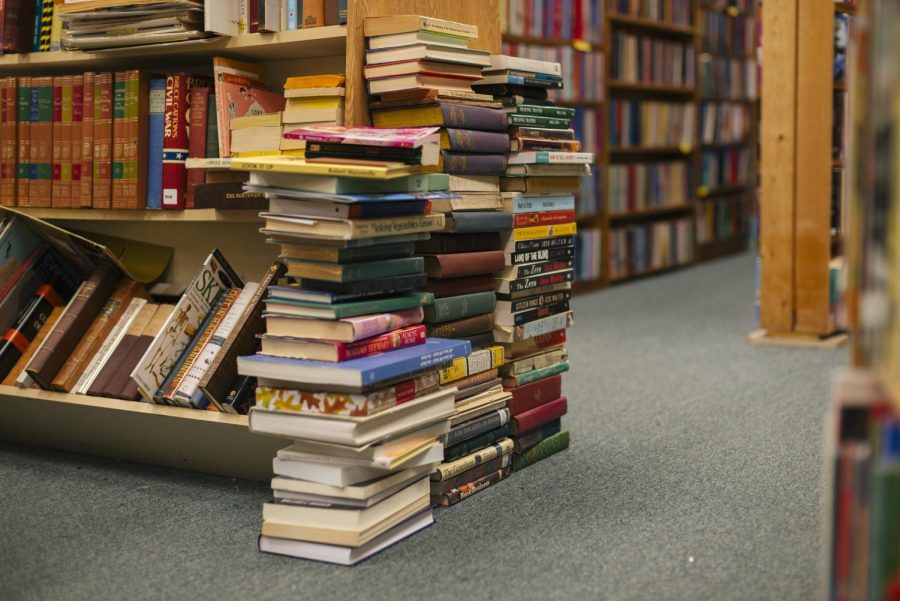

Oregon State University has been in the cheese business for over a hundred years. Right on the Corvallis campus, cows are milked and the cheese is processed and packaged, ready

to be sold.

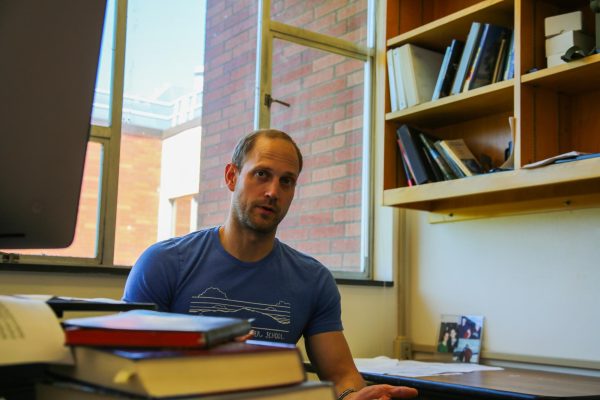

The creamery was reopened in 2010 after being closed for 50 years, said Robin Frojen, Creamery & Cheese Plant manager. Before it was closed down, the creamery produced all dairy products for the university.

Much of the Oregon dairy and cheese industry was upset that the state was funding the OSU dairy operation and allegedly supplying dairy at a lesser price. The department decided a decade ago that it was time to bring OSU Cheese back into business.

Robin Frojen attended OSU and graduated back in 2009. She said she remembers looking at the dusty, forgotten rooms in the back of Withycombe Hall wondering what it would take to get it going again. She was a chef for 20 years prior to coming to OSU and has always had an interest in food. In 2013 she began working for the creamery and hasn’t looked back since.

Frojen said the creamery now produces 12 different cheeses including cheddar, smoked swiss, guada, provolone and their 2016 award winning smoked cheddar. OSU took home a third place prize in the 2016 American Cheese Society’s Annual Competition for

their smoked cheddar.

Currently, 16 students work in the creamery. Aidan Long, a third-year food science major with a fermentation option, has been working in the creamery for two years. Terran Walker, also a food science major with a fermentation option, has been working at the creamery for about a year. They both got introduced to the cheese industry through a dairy processing class offered at OSU.

Student’s are recruited out of the class to work on the cheese production. Since beginning his work, Long said his perspective of the dairy industry has changed drastically.

“Since working here, it definitely makes me want to speak up when a lot of people talk about dairy cows being treated bad, or that people have a perspective of livestock being unhappy. Even just being in the class, it demonstrated to me that livestock live a really happy life,” Long said. “If you want good quality milk, you have to have happy cows. They are fed quite well and have a lot of roam around space.”

Walker said that there are a lot of misconceptions about the dairy industry and how it is bad for the environment, but that isn’t the case. The beef industry is what has created that stigma, being worlds away from the dairy industry, according to Walker.

On the mornings that the creamery makes cheese, students will go out to the farm around 6 a.m. and gather two-thousand pounds of milk from the cows, Frojen said. At 6:30 a.m. cleaning and set-up begins. This is the beginning of a long day ahead.

“Everything gets sanitized every day before we start processing, and then throughout the day there are students who are licenced pasteurizers and will pasteurize milk,” Frojen said. “Then a crew will put the cultures in, then ferment the milk and cut the curds, then another set with come in and do a lot of the work in between 2:30 p.m. to 6 p.m.”

Most of the day is spent waiting on the cheese to be ready before much of the work happens in the evening. One wrong measurement or ingredient could lead to students spending hours correcting the mistakes, so the staff rely on one another greatly.

“There were over 200 dairy processors in Oregon, and now there’s 12,” Frojen said.

The cows need to be milked and tended to twice a day by students with hands-on experience. “The dairy world is a 24-7 job. I always say that cows don’t take vacations. If they got themselves a union rep, I’m sure they would work that out,” Frojen joked.

Long and Walker both said they love working at the creamery and have thoroughly enjoyed experimenting and trying the cheeses. They spend most of their time cleaning and sanitizing, but are happy to do so to help the process.

“I would eat my breakfast off the floor of the creamery, it’s a lot of cleaning,” Long said.

OSU’s cheese can be found at Corvallis’ local Market of Choice and McMenamins.