Hard Work and Soft Robots

May 14, 2017

Bright light filters through tall windows, reflecting off of metal, plastic and rubber materials. On the second floor of Graf Hall, dozens of workstations create a maze of research projects. A tripod suspends a rubber octopus-like robot, the next table over supports a 3D printer and other stations contain countless wires and stacks of materials.

Unifying the vibrant range of research is robotics, in what’s known as the M-Lab. The ‘M’ stands for mechanics, manufacturing and materials. For Ph.D. students Callie Branyan and Chloe Fleming, soft robotics is their area of focus.

“The mission is to make soft robots a reality,” Dr. Yigit Menguc, Branyan and Fleming’s adviser, said. He initiated a project in the fall of 2016 to create a robot snake using soft robotics, a relatively new area in the field. Branyan and Fleming took on the project.

Fleming received her undergraduate degree in computer science from Arizona State University in 2013. After working at Intel for a couple of years, she decided to come back to school.

“I missed the challenge of this type of environment, the sort of open-ended research questions and a more fast-paced environment than the industry,” Fleming said.

At OSU, Fleming met Branyan, who received her undergraduate degree in mechanical engineering from University of Arizona.

“I chose it because it’s new and there’s a lot of collaboration,” Branyan said. “Because we’re doing something new, there weren’t gonna be a lot of answers, but I could come and find those answers.”

Branyan’s passion for robotics shows in her competence and enthusiasm in explaining the technical aspects of the machine. The team of two split the roles, with Branyan responsible for the mechanical and material side of the process, while Fleming figured out the gait (step-pattern) for the robot, and how to program it.

Soft robotics is ‘bio-inspired,’ according to Branyan, so the intention is to replicate living things in a way that rigid robots cannot.

Being nonlinear, soft robots are challenging to model. They are also difficult to build and replicate. The researchers stayed persistent through several designs.

The current snake robot, which is still developing, has one rigid component, a magnet, connecting two tube-shaped ‘log’ pieces, each about four inches long. The main body of the snake is made out of ecoflex 30, a flexible type of silicon.

The logs each have two air chambers running through them long-ways, which are connected to air tubes and can be pressurized individually to make the snake bend. The pattern at which they pressurize the air chambers results in different gaits. An elliptical cross-section prevents the robot snake from rolling over and sewing thread wraps around the logs in a double-helical cross pattern helps the snake move in the desired fashion. The snake moves forward by alternating S-shapes and C-shapes.

Since snakes can’t move on hard, flat surfaces without scales, the students put the robot snake in a granular medium to give it traction. By putting it in millet seed, they replicated swimming. They tested and wrote a paper on this stage and presented their findings at a conference in February. Since then, they also are experimenting with creating scales.

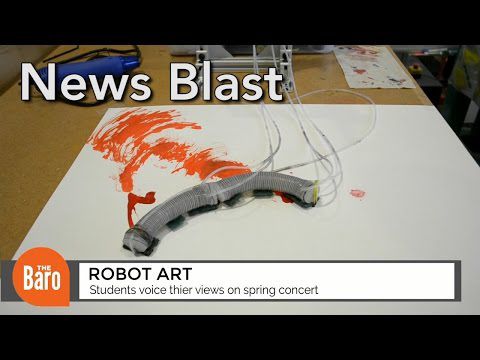

In April, Menguc discovered an art competition for robots, at robotart.org, run by a non-profit founded by Andrew Conru. This competition seeks to combine art and creativity with science and technology. Menguc encouraged Branyan and Fleming to enter.

“I only changed the design a little bit, basically sponges to put paint on, and have it kind of swim around the canvas,” Menguc said. The sponges act like scales, and the robot snake produces abstract art with many curves.

This year, 38 teams are competing for the $40,000 first prize, with lower increments for subsequent winners. The results will be released on Monday, May 15.

“We are the only soft robot in the competition,” Branyan stated, reflecting the novelty of their research, hoping it will give them an edge.

Menguc, Branyan, and Fleming all expressed pride in the current progress, as well as excitement for further research, including possibilities such as improving medical procedures, as well as search and rescue. Menguc brushed off his role in the process relative to his students.

“They’re the front line, they made it happen,” Menguc said.

However, Fleming shared the value of their advisor in the process.

“Our advisor deserves a lot of credit too,” Fleming said.